After getting my first real programming job, I have found that I type very slowly and that the mechanical keyboard I had purchased is too sensitive for my sloppy style. So, in the usual fashion, I have decided to shoot myself in the foot and create a keyboard to learn on.

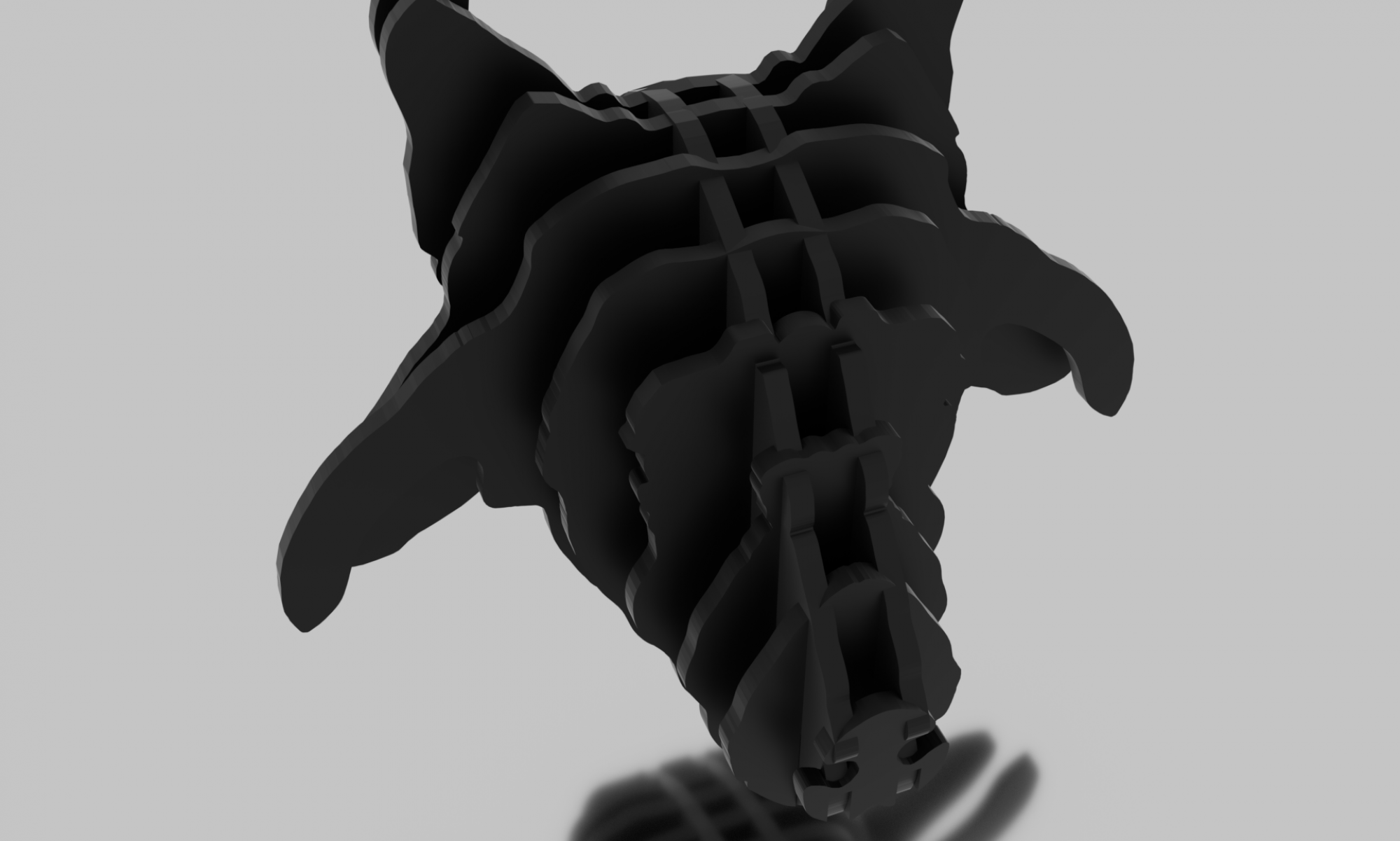

I had first heard about ergonomic keyboards from some white-collar salesmen at my first office job and decided to see how deep the rabbit hole currently is for ergonomic keyboards. I looked at this one, the Ergodox, the MoonLander, and finally the Dactyl. While the Dactyl has had several iterations, and I could use my prior knowledge of Blender to freehand a more customized keyboard, I decided to use the original method of using Clojure and OpenCad.

Step 1: Linux Environment

Load Ubuntu onto a laptop or set up a docker environment.

Tried both. My laptop is more feasible to use. It also helps to have a second computer with a Linux to run a wider variety of software.

Step 2: Learn Clojure or enough to modify

Have a rudimentary understanding of Clojure and use it to set up OpenCad system. The directions from the original Dactyl repo are easy enough to understand without a deeper understanding of Clojure. I was able to run the REPL from Leiningen and watch the model change in real-time. However, I was unsure how the keyboard would fit my hand and decided to use the bog-standard models.

Step 3: Printing and assembling

Having just moved to Baltimore I was unsure what resources were here for 3D printing. I initially looked in OpenWorks but, after a few attempts with using their printers, I was unable to get a single successful print. The printers were not in regular use and had various minor issues that prevented my prints from finishing.

Instead, I opted to use a 3d printing service. The Dactyl repo recommended Shapeways. Other options included: Xometry and ProtoLabs. However, these were all in the $300 – $400 range. At that price point, it would be cheaper for me to buy a Crealty Ender 3 and print it myself. I did strongly consider this option. The option I went with was Craftcloud3D, which subcontracts jobs to various small printers.

Now, I just have to wait for all my parts to arrive.