Prototypes 2

This round of prototypes was to expand on the first round and look into what worked and what didn’t work. Mostly, I worked on the techical implementation of the project and less on the role and look and feel. The role, I feel is fairly settled as an art installation piece. On the other hand, the look and feel will be heavily dictated by what is technically possible and what parts need to be incorporated into the project. Additionally, as the project is not handheld nor physically interacted with, the look and feel is not a primary factor in its usability.

There were two parts to my prototyping: coding and fabrication. In the last round of prototypes was able to write a Markov text generator that produced poems based on a large enough corpus. For this round, I worked and using speech recognition. This was a lot easier than I anticipated as most of the machine learning required for speech recognition was already done by Google and I was able to just use their API.

Link to github:

https://github.com/akierson/capstone-prototype

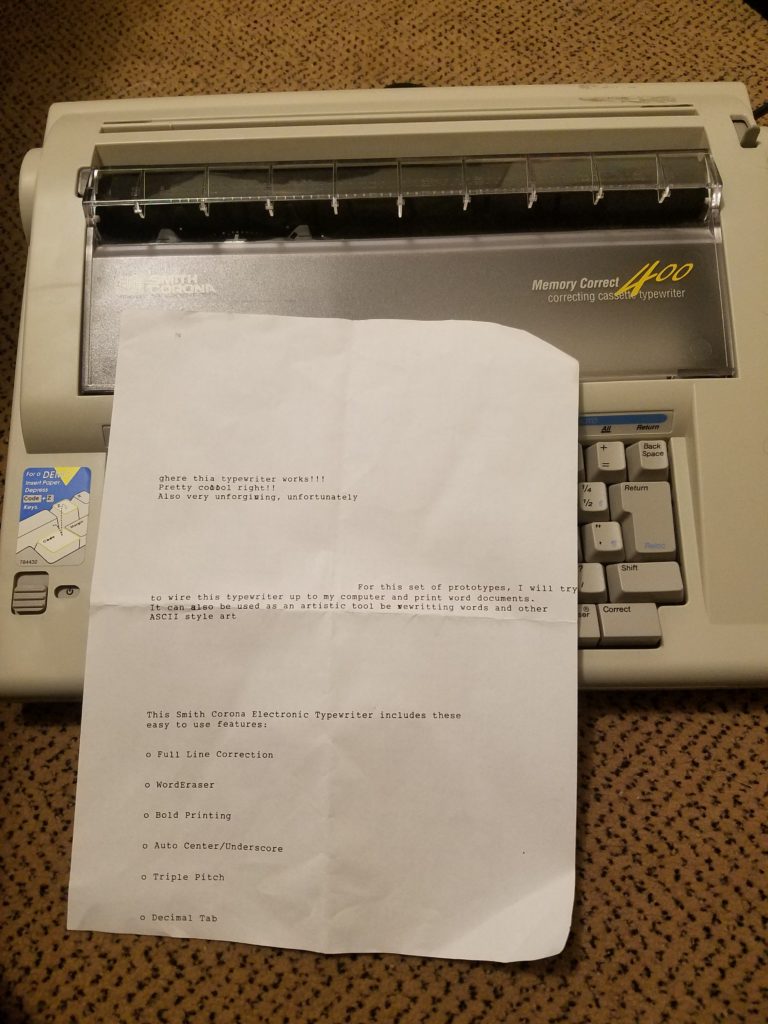

The fabrication was a bit harder. The typewriter I had purchased was luckily in perfect functioning order and all of the electronics and mechanical parts did not appear on their last leg despite being several decades old.

After testing that it worked, I tried to look for schematics on how they were wired. I was hoping to bypass the keyboard and only use the carriage for printing but I was unable to find any and the manufacturer has yet to contact me back.

I did try to hook up an Arduino to the carriage wiring but the Arduino was did not provide enough voltage and I was unwilling to try the 100V+ that some people online suggested.

Next, I took apart the keyboard to see if using solenoids was possible with the keyboard. I had expected the keyboard to have a mechanism more similar to today’s mechanical keyboards, but it instead had a rubber pad and keys without springs, instead relying on metal tabs to push the keys back up. The keys also have individual cases for a peg underneath them which I could potentially use to house a solenoid instead.

The smallest solenoids are about 12mm by 20mm with a 4mm pinhead. The head could easily take the place of the key peg and, with some sanding, the solenoids could replace the peg housing.