Project Milestone 1

While the project has taken a drastic turn from my initial plans when starting my warm-up project, it has come together nicely with manageable pitfalls.

The first pitfall I came across was my lack of skill in working with leather. I have previously sewed several items with cloth, including pants, blankets and a doll. Leather, unlike cloth, is a very tough material that usually requires specialized tools to score the leather, punch holes, and then stitch the leather. After looking into leatherworking most of the serious tools were more necessary for heavy leather, which the shoes I bought were not.

Another problem I came across was how to create the horns for the mask. My initial thought was to buy plastic tubing and then stretch the plastic into tapered horns. The type of plastic was fairly easy to decide on after a quick search on the available plastics at McGuckin’s. A propylethelene works best as it is thermoplastic, meaning it can be reshaped after heating, and does not release chlorine like thermoset PVC.

Unfortunately, plastic does not melt like metal and instead of stretching with gravity it tends to bunch up and become lumpy because of the uneven heating of a propane torch. I was able to create both a curled horn and a tapered one but both will need to be wrapped with cloth or leather. I may use metal or plastic piping to give a more stylized look instead of the quasi-realistic look I was hoping for with the plastic.

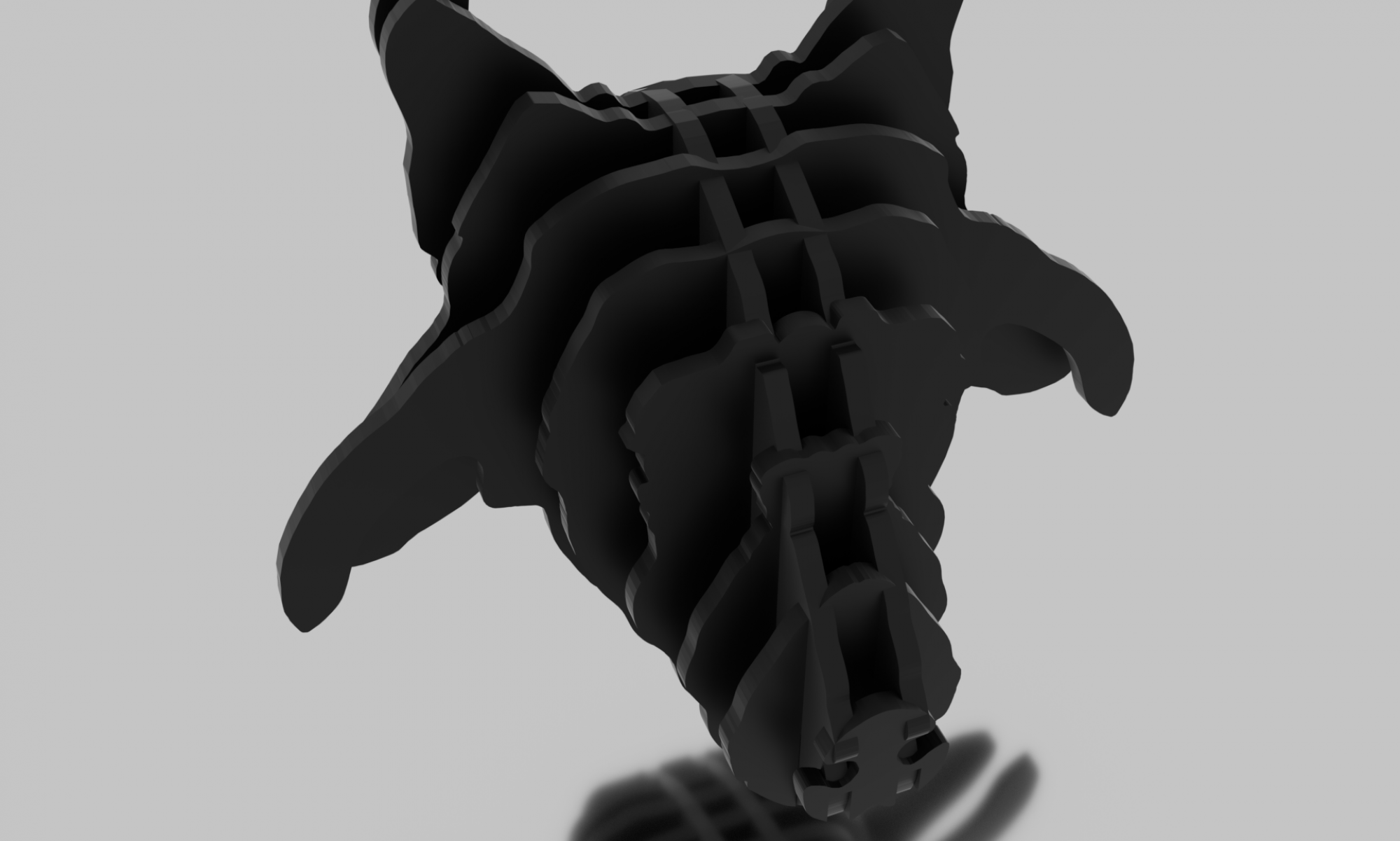

I still have a few changes which I may make going forward, including how the back of the mask looks, what the lights will light up to, and how the jawbone will connect to the leather.